Powder Handling & Pelletizing Equipment for the

Battery Industry

Partek provides comprehensive powder handling and pelletizing solutions for lithium battery manufacturing, addressing challenges such as dust leakage, handling of flammable, explosive, or toxic powders, and low operational efficiency across feeding, crushing, mixing, conveying, sieving, and packaging stages. Our complete systems cover the entire production process, from raw material input to final product discharge, ensuring a safer, cleaner, and more efficient battery material production line.

Recommended equipment for the battery industry

| Feeding of cathode and anode materials | Dust-free feeding station, Glovebox feeding station |

| Conveying of cathode and anode materials | Vacuum conveyor and enclosed conveying system |

| Crushing and screening of cathode and anode materials | Hammer mill Centrifugal sifter |

| Granulation and pelletizing for lithium anode materials | JYW extrusion–spheronization system |

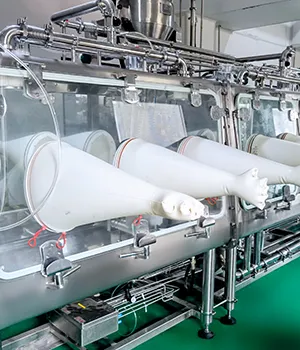

| Material filling and system integration | Moisture- and oxygen-free isolator |

Case Display

- Processed material: Lithium cobalt oxide cathode material

- Supplied equipment: Metering extrusion–spheronization equipment

- Processed material: LIBF, LIODFB, DTD

- Supplied equipment: Metering extrusion–spheronization equipment

- Processed material: Lithium fluoride

- Supplied equipment: Powder conveying–packaging system

- Processed material: Lithium battery additive

- Supplied equipment: Feeding–mixing–screening–packaging production line