Containment Glovebox (Reactor Charging Glovebox)

Powder handling glovebox for safe handling of potent powders and charging reactors in a sealed manner

- Overall dimensions: Customized

- Working pressure: -0.7kPa to +0.7kPa

- Optional features: Oxygen concentration monitoring

Nitrogen purging

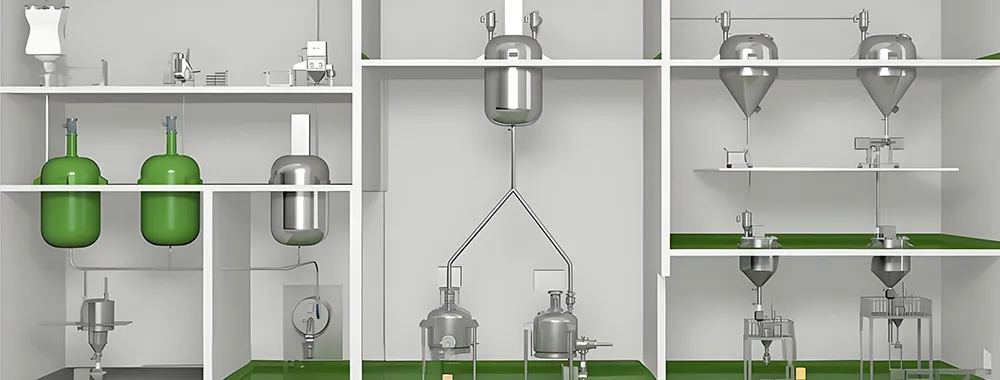

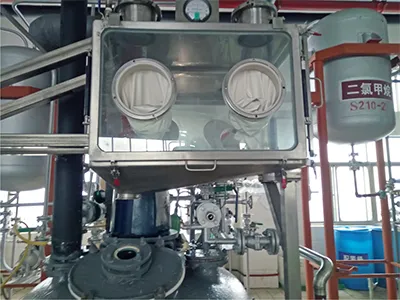

A containment glovebox is designed for the safe handling of potent or hazardous powders and charging of reactors under fully sealed conditions. The powder handling glovebox is generally integrated with vacuum conveying systems at the material discharging inlet, enabling fully enclosed powder transfer for sensitive or hazardous processes. The unit consists of a roller conveyor, unpacking chamber, collection chamber, dust extraction system, observation window, and anti-static gloves. The glovebox is available in SS304 or SS316L stainless steel, ensuring long service life and reliable performance in demanding environments requiring corrosion resistance.

- Complete containment and operator safety

The glovebox is equipped with an unpacking and collection chamber, ensuring full containment of toxic or corrosive powders. Anti-static gloves enable safe, sealed handling without operator exposure. Optional ATEX-certified components and oxygen concentration monitoring are available for flammable dust applications. - High-grade construction and compatibility

The main structure is made of high-quality SS316L stainless steel, ideal for strong acid or alkali environments. The interface system uses quick-clamp and flange connections, compatible with vacuum conveying systems. - Negative pressure dust extraction

Integrated dust collection system with 0.3 μm HEPA filtration keeps dust escape below 0.1%, maintaining cleanroom-grade containment. - Seamless line integration

The roller conveyor enables automatic bag transfer into the glovebox for unpacking, followed by vacuum conveying directly to the reactor. This reduces manual handling steps. Optional CIP cleaning system completes automated cleaning within 30 minutes while reducing water consumption by 40%. - Versatile industry adaptability

Suitable for a wide range of industries from pharmaceutical and chemical production to new energy materials processing, wherever safe, enclosed powder handling is required.

- Discharging of corrosive or toxic powders (e.g., pesticides), providing operator protection

- Handling and transfer of lightweight materials

- Safe discharging of flammable materials or use in explosion-proof environments such as alumina processing

- Reactor charging operations in pharmaceutical, chemical, and specialty material production

Lithium cobalt oxide

Lithium cobalt oxide Imidacloprid

Imidacloprid Silver powder

Silver powder

Structural Component Customization

| Module | Customization options | Application scenario |

| Roller conveyor system | Length:1–5 m;Load capacity:50–500kg | Suitable for small bag (25kg) or drum discharging |

| Unpacking chamber | Dual-station configuration;Explosion-proof viewing window | High-frequency discharging lines |

| Collection chamber | Conical hopper with vibration and de-clogging device | Materials prone to agglomeration |

| Glove operation ports | Quantity:1–4 pairs;Material:Acid-resistant rubber gloves | Corrosive or toxic materials |

Material Upgrade Options

| Component | Material options |

| Main frame | SS316L stainless steel (default:SS264) |

| Inner wall & hopper | SS316L stainless steel |

| Sealing parts | Fluororubber (FKM) |

Dust Control Customization

| Module | Customization options |

| Dust extraction system | Basic version:single-point suction (airflow 200 m³/h);Enhanced version:multi-point vortex extraction (airflow 500 m³/h) with 0.3 μm HEPA filter |

| Negative pressure monitoring | Integrated differential pressure sensor automatically adjusts airflow to maintain negative pressure ≥ -50 Pa in the unpacking chamber |

Explosion-Proof and Safety Enhancements

| Risk type | Customized solution | Applicable materials |

| Electrostatic ignition | System-wide grounding with anti-static gloves and ionizing air bar | Aluminum powder / coal dust |

| Flammable gas | Oxygen concentration sensor with automatic nitrogen purging (O₂ <5% LEL) | Lithium battery materials / sulfur powder |

| Mechanical sparks | ATEX-certified explosion-proof motor with tool-free disassembly components | Metallic nanopowders |

Cleaning System Upgrade

| Cleaning requirement | Customized solution |

| Routine cleaning | Detachable design with cleaning ports |

| Sterile environment | CIP (Clean-in-Place) system with 3D rotary spray balls |

| Drying and moisture prevention | Hot air purge function |

The containment glovebox can be integrated with vacuum conveying systems for fully enclosed powder transfer.

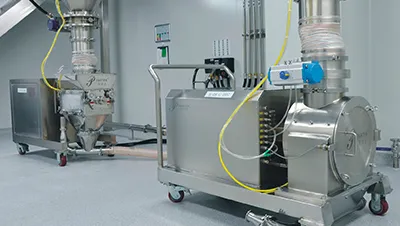

Reactor charging process at a pharmaceutical company

Reactor charging process at a pharmaceutical company Contained powder handling at an agrochemical plant

Contained powder handling at an agrochemical plant Reactor charging operation at a pharmaceutical production site

Reactor charging operation at a pharmaceutical production site