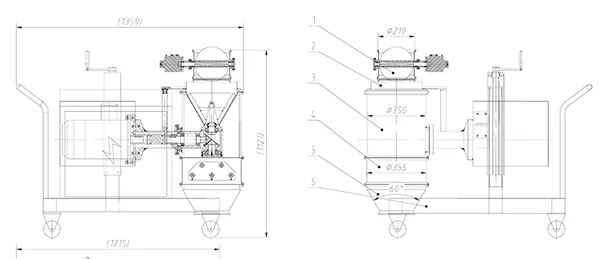

Conical Mill, PRM Series

Conical sieve granulating machine for milling of wet or dry granules in pharmaceutical, food, and chemical processes

The conical mill is designed for milling wet materials in pharmaceutical, food, and chemical industries. It features a vertical conical screen that ensures uniform particle distribution and high throughput. Depending on the properties of the material, round-hole, square-hole, or rasp-type screens can be selected. With a large screening area and a high-speed rotating rotor, the PRM conical mill can achieve a processing capacity of up to 1500kg/h.

| Model | Processing capacity | Effective screen area | Voltage | Motor speed | Power | Net weight | Remarks |

| 100–400kg/h | 125cm² | 3 phase,380V,50Hz | 500–1500rpm | 2.2kW | 100kg | Synchronous belt drive | |

| 150–1200kg/h | 400cm² | 3 phase,380V,50Hz | 500–1500rpm | 3kW | 150kg | Helical gear drive | |

| 150–1200kg/h | 400cm² | 3 phase,380V,50Hz | 500–1500rpm | 4kW | 250kg | Synchronous belt drive | |

| 400–1500kg/h | 780cm² | 3 phase,380V,50Hz | 500–1500rpm | 5.5kW | 320kg | Synchronous belt drive |

- Interchangeable rotors for both dry and wet milling applications

- Simple installation design with an error-proof locking system for secure assembly

- Modular structure offering flexible configuration to meet various process requirements

- Adjustable clearance between rotor and screen based on material characteristics

- Rotary granulation design ideal for post-fluid bed processes

- Removable milling chamber for easy cleaning and sterilization

- Optional waterproof, dustproof, and explosion-proof configurations available

Sodium carboxymethyl cellulose

Sodium carboxymethyl cellulose Instant coffee granules

Instant coffee granules

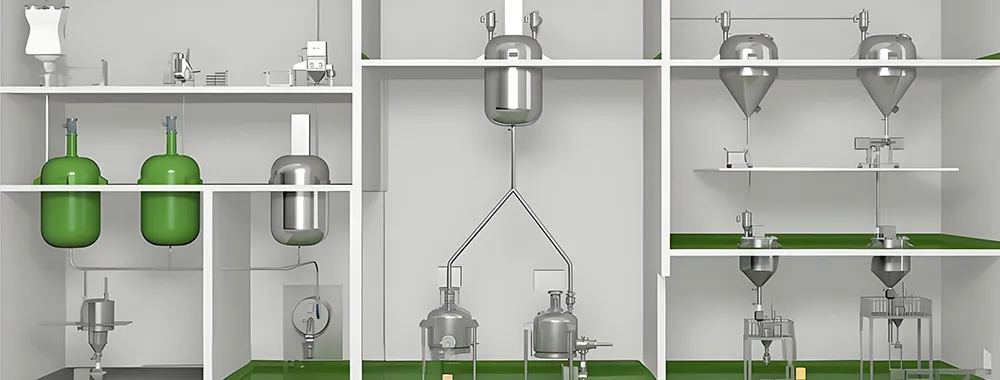

The conical mill can be integrated with our sieving machines and vacuum conveying systems to form a complete processing line tailored to different production needs.