Oscillating Granulator, BFJ Series

Particle size reduction machine for transforming dry or wet materials into precisely sized granular products

Designed for both dry and wet material milling, the oscillating granulator is particularly suitable for temperature-sensitive or difficult-to-process materials. The milling knives operate in a rotary oscillating motion, and by adjusting the oscillation speed together with the appropriate sieve type, optimal milling results can be achieved, reaching a fineness of up to 60 mesh. Depending on the material properties, different sieve types can be selected, including round wire, square wire, or perforated plate sieves. Custom configurations are also available to meet specific process requirements.

| Model | Processing capacity | Voltage | Rotor speed | Power | Net weight (without base) | Net weight (with base) |

| 300–800kg/h | 3 phase,380V,50Hz | 27–155rpm | 2.2kW | 285kg | 335kg | |

| 500–1500kg/h | 3 phase,380V,50 Hz | 27–155rpm | 2.2kW | 320kg | 370kg |

- Low-speed milling mechanism that minimizes heat generation during operation

- Rigid base structure ensures accurate spacing between rotor and sieve, preventing direct mechanical contact

- Gentle grinding and granulation, suitable for both dry and wet materials as well as for screening heat-sensitive powders, especially ideal for use with wet granulation processes

- Contact-free rotor and sieve design with infinitely adjustable clearance

- Modular construction allows flexible integration into complete process lines

- Quick disassembly of sieve, rotor, and base for easy cleaning and maintenance

- Multiple sieve options available: round wire, square wire, or perforated plate

- Optional cleaning nozzles for automatic washing

- Optional safety configurations, including waterproof, dustproof, and explosion-proof designs

- Complies with CIP, SIP/WIP requirements and meets FDA and GMP standards for hygienic processing

Phthalocyanine blue

Phthalocyanine blue Seasoning powder

Seasoning powder

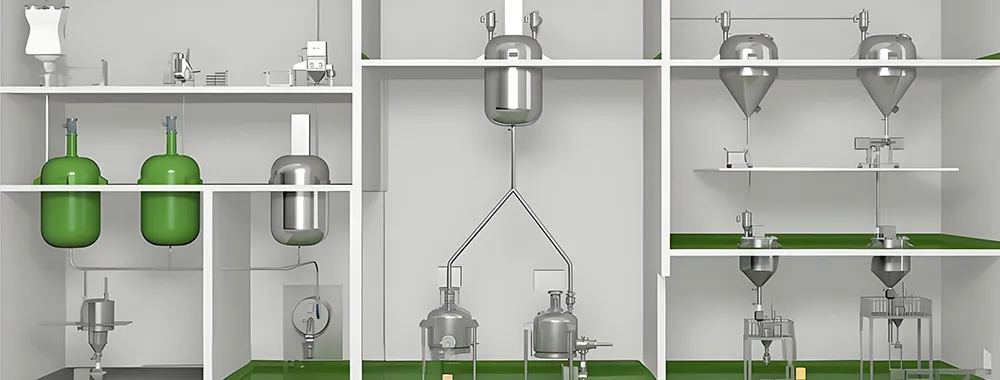

This oscillating granulator can be integrated with vacuum conveyors, sieving machines, mixers, and small or bulk bag feeding stations to form a complete processing system tailored to different production needs.