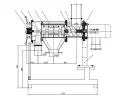

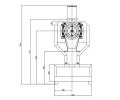

Rotary Centrifugal Sifter (Single Shaft)

Rotary sifter machine for separating and sieving of powders and granules of various sizes using centrifugal force

The rotary centrifugal sifter is designed for precise separation and sieving of powders and granules through the action of centrifugal force. Material is fed into the rotating chamber via a screw conveyor, where high-speed rotating blades efficiently classify and screen particles. Fine material passes through the mesh into the collection chamber, while oversized particles are automatically discharged for reprocessing.

This horizontal sifting machine is widely used in the pharmaceutical, food, and chemical industries for powder screening and particle classification, offering high performance and excellent production efficiency.

| Item | Product contact parts | Non-contact parts |

| Material | AISI 316L stainless steel | AISI 304 stainless steel |

| Surface finish | Ra≤0.8μm,polished finish | Ra ≤1.4μm,ground finish |

| Welding | Ground and polished | Pickled and ground |

| Processing capacity | 200kg/h | |

| Rotation speed | 1500rpm | |

| Power | 1.1kW | |

| Net weight | 250kg | |

- Fully enclosed design to prevent product contamination

- No metal-to-metal contact during operation

- Quick-release structure for fast disassembly and easy cleaning

- Airtight bearing design for long service life

- Adjustable speed control with optional digital display

- Integrated, user-friendly design delivering efficient and consistent sifting results

Pigments

Pigments Food additives

Food additives Active pharmaceutical ingredients (APIs)

Active pharmaceutical ingredients (APIs)

- Structural customization

Adjustable inlet and outlet dimensions and orientations - Design customization

Options for material selection, surface finishing, and mobile frame configuration - Functional customization

Available choices include mesh size, sifting motor specifications, control system integration, vacuum feeding interface, explosion-proof construction, and optional CIP (Clean-in-Place) system

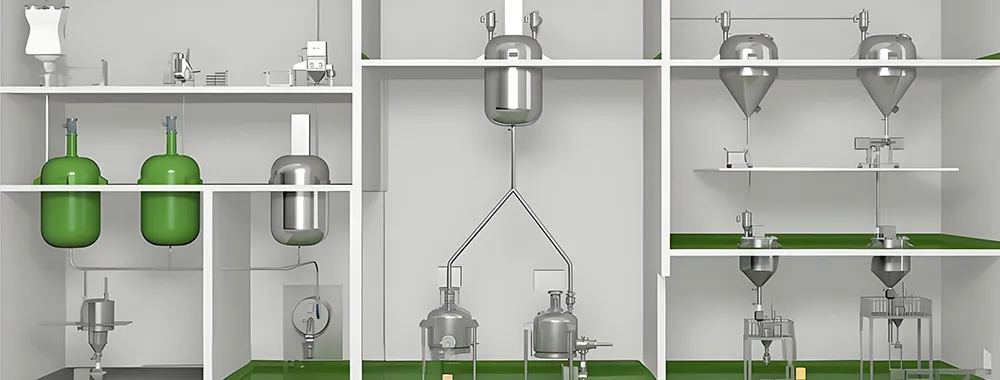

This rotary centrifugal sifter can be combined with our vacuum feeding system and hammer mill to create a complete and efficient powder processing line tailored to specific production needs.