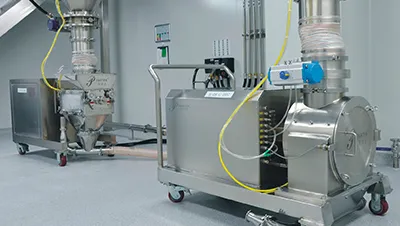

Centrifugal Pelletizer

Centrifugal pelletizing machine combining granulation and coating processes for converting fine powder materials into granular products

The centrifugal pelletizer integrates granulation and coating into a single continuous process. Fine powders are introduced into the processing chamber, where a fine mist of binder solution is sprayed to bind the particles together and initiate seed granulation. The resulting seed granules are dried and then reintroduced with additional powder and binder for layering and growth, forming dense, uniformly sized spherical pellets with excellent roundness. By spraying atomized coating liquid onto the finished pellets, a uniform and continuous film layer is formed, making this system ideal for producing coated microgranules and controlled-release pharmaceutical pellets.

| Model | ||||

| Pellet diameter | 0.2mm | 0.5mm | 2.0mm | 5.0mm |

| Production capacity (blank pellets) | ≤2.5kg/batch | ≤10.0kg/batch | ≤20.0kg/batch | ≤50.0kg/batch |

| Enlargement ratio | ≤2 | |||

| Disc diameter | 300mm | 500mm | 700mm | 1000mm |

| Main motor power | 1.5kW | 3kW | 7.5kW | 11kW |

| Blower power | 0.75kW | 1.5kW | 2.2kW | 4kW |

| Exhaust fan power | 0.55kW | 0.75kW | 1.5kW | 2.2kW |

| Rotation speed | 50–1400rpm | 50–1400rpm | 50–1200rpm | 50–400rpm |

| Steam pressure | 0.4–0.7MPa | |||

| Steam consumption | 5kg/h | 8kg/h | 12kg/h | 14kg/h |

| Compressed air pressure | 0.4–0.6MPa | |||

| Compressed air consumption | 0.5m³/min | 0.7m³/min | 0.9m³/min | 1.1m³/min |

| Operating temperature | Room temperature to 100°C (automatic control) | |||

| Noise level | ≤60dB | |||

| Overall dimensions (L×W×H) | 760×700×1133mm | 1100×860×1055mm | 1400×1150×1359mm | 1800×1300×1400mm |

| Net weight | 300kg | 450kg | 600kg | 1600kg |

Sustained-release pellets

Sustained-release pellets