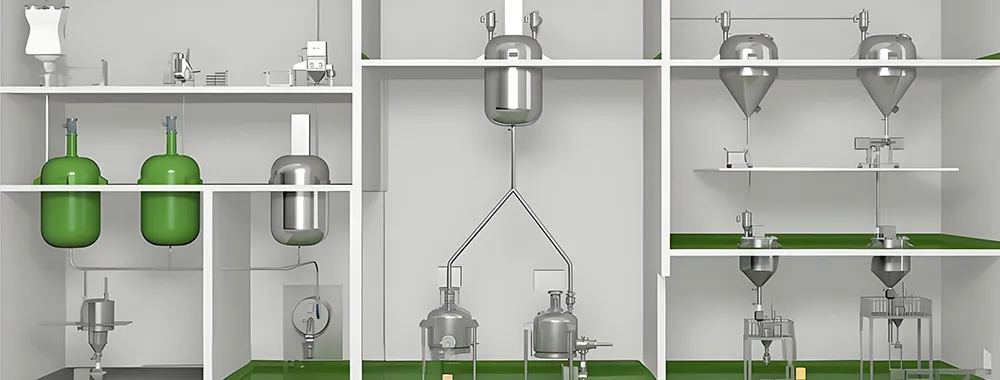

Big Bag Discharging Station

Bulk bag unloader for dust-free discharge of powders and dry bulk materials from big bags (FIBCs) into a powder processing system

- Applicable bag: FIBC bulk bags (tonne bags)

- Hoist lifting capacity: 0.2-1.5T

- Working pressure: 0.5-0.6MPa

- Operating temperature: -20℃ to 45℃

The big bag discharging station lifts the FIBC to the feed inlet, where the operator manually releases the bag outlet tie and initiates discharge. A bag agitation device assists the smooth flow of powder or granular material by gravity into the buffer hopper, from which a screw conveyor transfers the material to the next process stage. This setup ensures clean, efficient, and controlled unloading suitable for pharmaceutical, chemical, and food industries.

Features

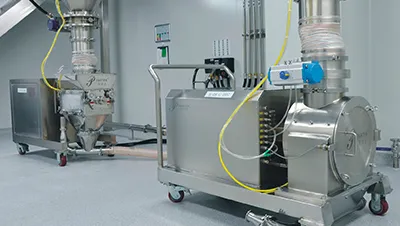

- Safe and reliable structure

Product contact parts are available in SS304 (food grade) or SS316L stainless steel for corrosion resistance and compliance with hygiene standards in pharmaceutical and chemical environments. - Reduced manual handling

The big bag is lifted by an electric hoist and secured to a rigid frame. Operators can control lifting and positioning along a traveling rail system to place the bag accurately above the discharge area. After unloading, the clamp mechanism releases the empty bag, allowing safe and convenient removal.

Typical Applications

Coffee beans

Coffee beans Food additives

Food additives Inulin

Inulin

Customizable Options

- Core functional modules

Load capacity: Configurable for FIBC bags ranging from 200 to 1500kg

Equipment dimensions: Adjustable in length, width, and height according to plant layout or space constraints

Material construction: Product contact surfaces available in SS304 (food grade) or SS316L stainless steel for corrosion resistance in pharmaceutical and chemical applications - Adaptation for special conditions

Sealed and eco-friendly design: Fully enclosed structure prevents dust leakage and ensures clean operation

Inert gas protection: Optional nitrogen purging system for flammable, explosive, or oxidation-sensitive materials - Structural and configuration options

Lifting system: Custom electric hoist design supporting 1–3 ton lifting capacity with tailored lifting height

Downstream connectivity: Compatible with silos, screw conveyors, or tubular chain systems; customizable flange interfaces available for seamless integration