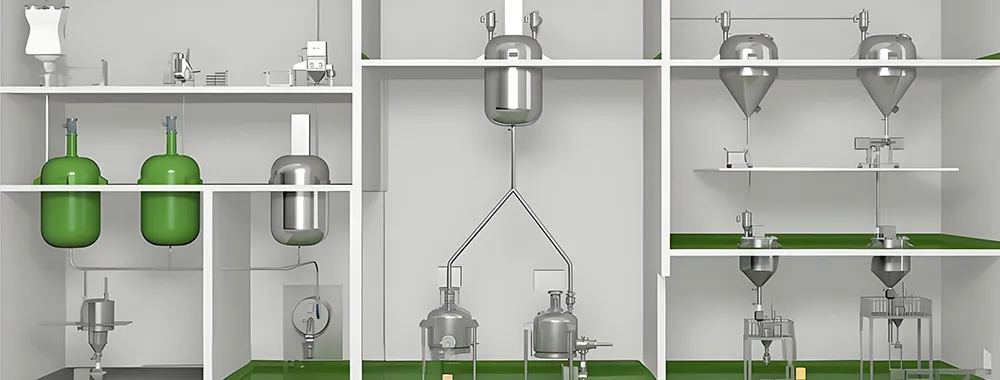

Integrated FIBC & Small Bag Discharging System

A combined unloading system integrating big bag discharging station, lump breaker and small bag dump station

The powder unloading system consists of a vibrating-type big bag discharging station, crusher, small bag dump station, dust collection system, pneumatic rotary valve, and U-type screw conveyor. During operation, material from the FIBC is lifted by an electric hoist and unloaded through the vibrating discharging station. The discharged material passes through the crusher, enters the small bag dump station, and is then filtered and collected by the dust collection system.

Any metal impurities are removed through a magnetic separator before the material is transferred via the rotary valve and U-type screw conveyor to the next process step.

- Integrated all-in-one design

Combines six key modules: big bag unloading, small bag unloading, crushing, dust collection, iron removal, and conveying into a single compact system. Each stage connects seamlessly for efficient operation and easy maintenance. - Versatile discharging compatibility

Handles both FIBC and small bag materials, adaptable to various production needs and suitable for raw materials, intermediates, and multi-type powders. - Highly efficient dust collection

Equipped with a pulse jet dust collector for automatic dust recovery, maintaining a clean feeding environment in compliance with GMP and FDA cleanroom standards. - Improved downstream stability

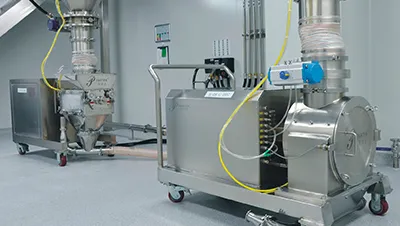

Integrated crushing and iron removal modules ensure smooth downstream processing. The crusher breaks up agglomerated materials, while the high-strength magnetic separator eliminates metal contaminants, improving product quality. - Compact and intelligent conveying

The U-type screw conveyor provides smooth material transfer and space-efficient design, ideal for small and medium-sized plant layouts. - High automation and connectivity

Optional PLC control and integration with MES or supervisory systems enable real-time monitoring, automated control, and production traceability. - Customizable configuration

Modular design allows customization of crusher screen size, magnetic intensity, and hopper capacity based on material characteristics and throughput requirements.

Mixed spices

Mixed spices