Containment Charging Isolator

Glovebox isolator feeding system for transferring powders from bags into process equipment under contained conditions

- Overall dimensions: Customized

- Working pressure: -0.7kPa to +0.7kPa

- Optional features: Oxygen concentration control

Nitrogen purging

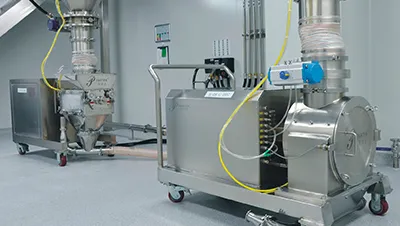

The containment charging isolator provides a sealed solution for powder discharging and transfer. Material bags are conveyed via roller tracks and passed through a transfer window into the operating chamber. Operators handle the bags through glove ports to open and empty the contents, while waste bags are collected automatically through a dedicated waste recovery unit. The entire operation is fully enclosed, preventing dust escape and ensuring operator safety. This containment isolator supports online cleaning (CIP) and can be customized for different materials and processes.

- Dust-free protection

Dual-seal design with transfer window and negative-pressure dust extraction ensures a clean and contained working environment. - Operator safety through isolation

Closed-loop glove port design enables safe, contact-free discharging of corrosive or moderately toxic powders. - Intelligent waste collection

Automatic waste bag collection unit slides used bags into a sealed compartment, eliminating manual cleaning and secondary contamination. - Automated cleaning (CIP)

Fully automatic clean-in-place system simplifies maintenance and prevents cross-contamination. - Integrated powder handling

The containment isolator can be seamlessly connected with vacuum conveyors or big bag discharging stations, forming a fully enclosed discharging–conveying–dosing circuit for safe, efficient powder management.

- Discharging of corrosive or toxic powders

- Contained handling of high-value or sensitive powders

- Integration with vacuum conveying systems for a fully enclosed discharging and conveying loop

Aluminum chloride (chemical raw material)

Aluminum chloride (chemical raw material) Silver powder

Silver powder

- Structure & function

Inert gas protection: Nitrogen or argon purging to prevent oxidation or combustion during powder discharging

Anti-clogging & fluidization design: Optional vibration or airflow assistance to ensure smooth and continuous material discharge

Antistatic treatment: Surface coating or ionized air system for handling electrostatically sensitive materials - Size & compatibility

Hopper capacity: Configurable from 50 L to 2000 L, compatible with both small bag and FIBC discharging

Interface options: Available with flange or quick-connect fittings for easy integration with downstream equipment - Cleaning & safety

Clean-in-Place (CIP): Fully automatic washing system designed in compliance with GMP requirements

Explosion protection & monitoring: Supports ATEX-certified design and real-time dust/gas detection - Automation integration

PLC + HMI control system: Enables recipe management, operator access control, fault alarm, and automated discharging record tracking

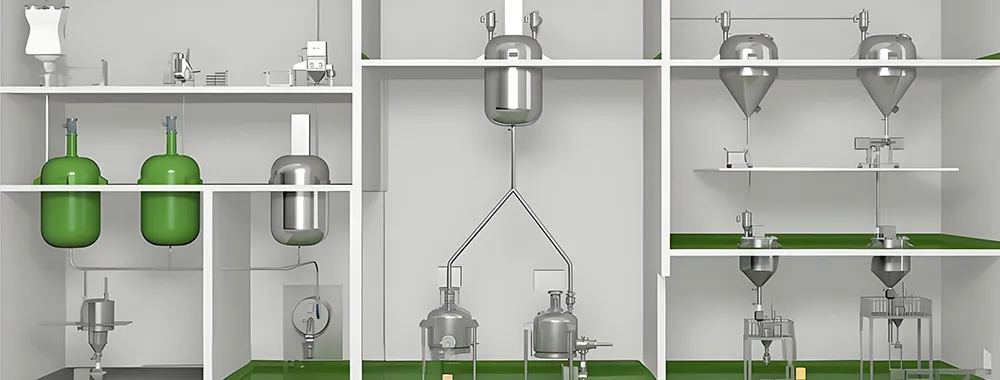

The containment charging isolator can be seamlessly integrated with vacuum conveying systems to form a fully enclosed and automated powder handling line.