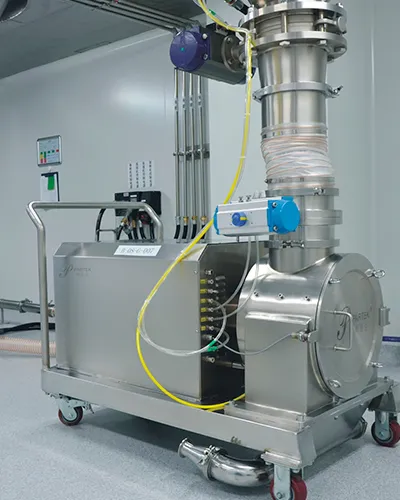

Hammer Mill, CFJ Series

Particle size reduction machine for crushing dry materials into fine powders

The hammer mill is designed for efficient size reduction of powders and granules. Material is evenly fed into the milling chamber through a rotary valve, where high-speed rotating blades apply impact and shear forces to achieve fine and uniform particles with a milling precision of up to 200 mesh.

- Dead-corner-free milling chamber for easy cleaning and maintenance

- Modular design adaptable for various process requirements

- Equipped with automatic protection against overheating and overloading

- Adjustable rotor speed ranging from 2500–6000 RPM

- Quick disassembly of rotor and screen for easy cleaning and safe operation

- Controlled screening delivers uniform particle size and steady throughput

| Model | |||

| Processing capacity | 200–300kg/h | 400–800kg/h | 600–1000kg/h |

| Power | 4kW | 5.5kW | 7.5kW |

| Dimensions (L×W×H) | 700×800×1200mm | 800×800×1350mm | 900×800×1400mm |

Active pharmaceutical ingredients (APIs)

Active pharmaceutical ingredients (APIs) Active pharmaceutical ingredients (APIs)

Active pharmaceutical ingredients (APIs)

Depending on the material characteristics and the target particle size, different sieve sizes can be customized. For heat-sensitive materials, an optional cooling system is available to maintain product stability during milling.

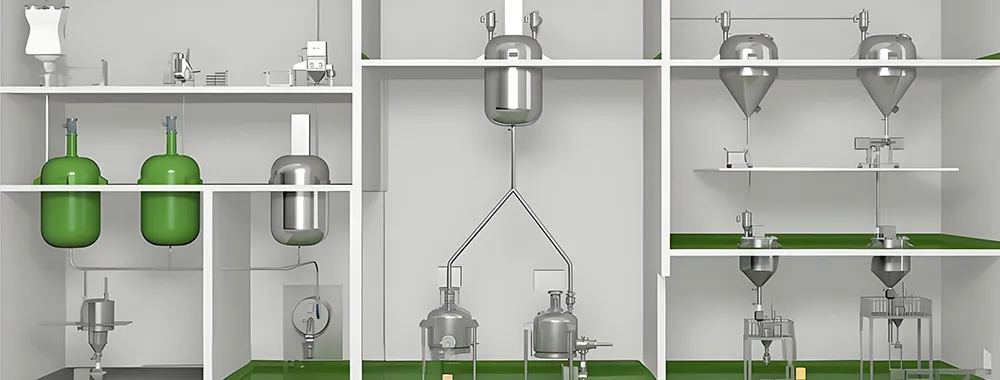

This hammer mill can be integrated with vacuum conveyors, screening machines, and weighing and packaging systems to form a complete processing line tailored to various customer requirements.

Powder milling of pharmaceutical materials

Powder milling of pharmaceutical materials Milling of additives

Milling of additives Milling of feed ingredients

Milling of feed ingredients On-site milling of cosmetic raw materials

On-site milling of cosmetic raw materials