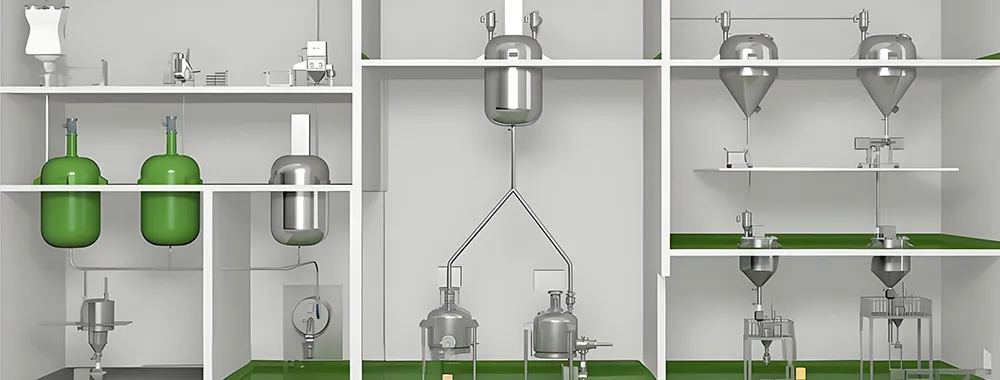

Vacuum Conveying Equipment

Vacuum feeding machines for transporting bulk powders, granules and small parts through hoses and pipes

Vacuum conveying equipment provides a clean, enclosed, and efficient way to transport powders, granules, and small components through hoses or pipelines using compressed air suction. It is widely applied in pharmaceutical, chemical, food, and related industries for transferring materials such as powders, pigments, dust, tablets, capsules, grains, and micro parts. The powder handling system features easy installation, simple operation, and fully enclosed transfer, preventing leakage and eliminating dust dispersion throughout the conveying process.

Customizable Options

To meet various process requirements, the powder conveying equipment can be tailored in the following aspects:

- Structural dimensions: Adjustable conveying pipe diameter, storage hopper capacity, conveying height and distance, and connection interface types

- Exterior configuration: Material selection, polishing precision, color finish, and dustproof or explosion-proof design

- Functional modules: Control mode, filtration system, feeding and discharging methods, and optional functions such as CIP cleaning and alarm systems

-

- Vacuum Feeder, VP Series The VP series vacuum feeder consists of a vacuum system, back-blow cleaning system, filtration system, inlet butterfly valve, and discharge butterfly valve. The vacuum system can be configured either with a built-in pneumatic vacuum pump or an external vacuum source.

- Compressed air pressure

0.5–0.8MPa - Working pressure

0.5–0.8MPa - Air consumption

0.4-3.6m³/min - Conveying capacity

2.0–4.0T/h

- Compressed air pressure

The continuous vacuum feeder is one of our patented practical designs for efficient and enclosed powder conveying. Using compressed air suction, it transfers powders, dust, pigments, granules, tablets, capsules, agricultural materials, and small components through flexible hoses or pipelines. Unlike traditional batch vacuum feeders, this vacuum conveying equipment enables continuous feeding and continuous discharging, significantly enhancing conveying efficiency while conserving vacuum resources. The powder handling system features simple installation, convenient operation, and fully enclosed transfer, ensuring zero leakage and dust-free performance throughout the process.

-

- BVP Continuous Vacuum Feeder The BVP continuous vacuum feeder operates by connecting two vacuum conveyors equipped with butterfly discharge valves in parallel.

- Compressed air pressure

0.5–0.8MPa - Working pressure

0.5–0.8MPa - Air consumption

0.4-3.6m³/min - Conveying capacity

3.0–6.0T/h

- Compressed air pressure

-

- CVF Continuous Vacuum Feeder The CVF continuous vacuum feeding system consists of a vacuum valve chamber, isolation chamber, filter unit, reverse air cleaning system, feeding mechanism, and rotary airlock valve.

- Compressed air pressure

0.5–0.8MPa - Working pressure

0.5–0.8MPa - Air consumption

0.4-3.6m³/min - Conveying capacity

3.0–6.0T/h

- Compressed air pressure

-

- Mobile Vacuum Feeder The mobile vacuum feeder consists of a vacuum system, back-blow cleaning system, filtration system, inlet and discharge butterfly valves, and a movable caster-mounted frame.

- Compressed air pressure

0.5–0.8MPa - Working pressure

0.5–0.8MPa - Air consumption

0.4-3.6m³/min - Conveying capacity

2.0–4.0T/h

- Compressed air pressure