Vacuum Feeder, VP Series

Powder handling glovebox for safe handling of potent powders and charging reactors in a sealed manner

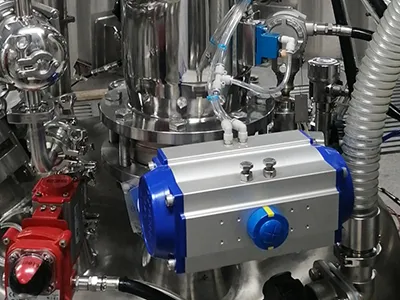

The VP series vacuum feeder consists of a vacuum system, back-blow cleaning system, filtration system, inlet butterfly valve, and discharge butterfly valve. The vacuum system can be configured either with a built-in pneumatic vacuum pump or an external vacuum source.

Under negative pressure generated by the vacuum system, materials are drawn through the suction pipe into the storage hopper. The integrated filter separates air from solid particles, preventing powder from entering the vacuum unit. The feeder operates automatically in a suction–discharge–back-blow cycle, ensuring continuous and efficient conveying. Explosion-proof versions are available for transferring reactive media to reactors or mixing tanks.

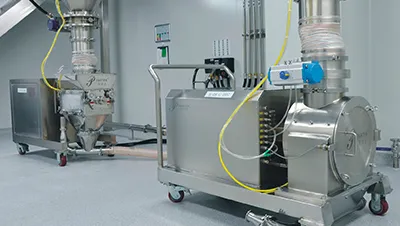

The VP vacuum feeder is widely used for enclosed conveying of powders, granules, and small flakes, especially in industries with stringent cleanliness requirements such as pharmaceuticals, food additives, and fine chemicals.

| Model | ||||

| Vacuum generator model | VTML100 | VTML200 | VTML400 | VTML600 |

| Compressed air pressure | 0.5–0.8MPa | 0.5–0.8MPa | 0.5–0.8MPa | 0.5–0.8MPa |

| Working pressure | 0.5–0.8MPa | 0.5–0.8MPa | 0.5–0.8MPa | 0.5–0.8MPa |

| Air consumption | 0.4m³/min | 0.8m³/min | 1.8m³/min | 3.6m³/min |

| Conveying capacity | 0.1–0.3T/h | 0.3–0.9T/h | 0.9–2.2T/h | 2.0–4.0T/h |

| Filter | Ti07 inlet filter, PTFE filter, PE-HD filter, sintered Ti filter | Ti07 inlet filter, PTFE filter, PE-HD filter, sintered Ti filter | PE-HD filter, sintered Ti filter | PE-HD filter, sintered Ti filter |

| Filter area | 0.3m² | 0.3m² | 0.9m² | 1.8m² |

| Suction inlet diameter | DN25 | DN50 | DN75–50 | DN100–75 or DN100 |

| Discharge outlet diameter | 150mm | 150mm | 200mm | 200mm |

| Hopper volume | 5 L | 12 L | 22 L | 50 L |

- Operating noise below 70 dB; pneumatic vacuum feeder consumes less than 1kW

- Provides fully enclosed, dust and contamination-free material transfer

- Compact structure with overall height under 1.2 m and diameter below 600mm, ensuring easy installation

- Optional mobile design for flexible positioning in production areas

- Designed in accordance with GMP requirements and supports clean-in-place (CIP) cleaning

- Equipped with static elimination and inert gas purging to safely handle flammable gases inside the hopper

Food additives

Food additives Chemical raw materials

Chemical raw materials Active pharmaceutical ingredients (APIs)

Active pharmaceutical ingredients (APIs)

The VP vacuum feeder can be integrated with small bag discharging stations, hammer mills, horizontal centrifugal sifters, and weighing and packaging systems to form a complete powder handling line that meets diverse production requirements.

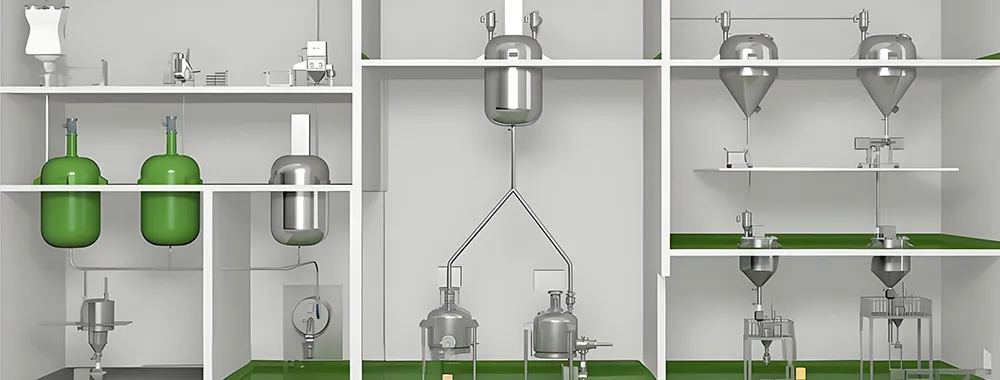

Reactor charging process at a pharmaceutical company

Reactor charging process at a pharmaceutical company Integrated horizontal dryer system

Integrated horizontal dryer system Integrated reactor feeding system

Integrated reactor feeding system Integrated reactor feeding system

Integrated reactor feeding system