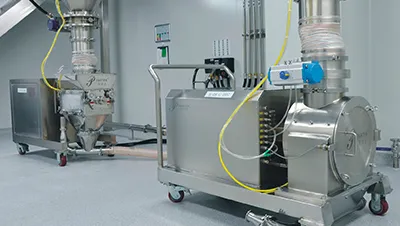

Laboratory-Scale Spheronizer (Marumerizer)

Laboratory granulation equipment for converting cylindrical extruded granules into uniform round pellets in small batches

The laboratory spheronizer is developed for research and small-batch production environments, featuring a compact footprint, lightweight construction, and user-friendly operation. It efficiently transforms cylindrical extrudates into uniform, spherical pellets through a high-speed centrifugal process.

During operation, the cylindrical granules are introduced onto a rotating friction plate equipped with cutting teeth. The material is evenly cut into short cylinders, which are then shaped into smooth, dense spheres under the combined effects of centrifugal force, inter-particle friction, wall contact, and air movement within the chamber. This ensures a consistent spheronization process and uniform pellet geometry.

The spheronization machine consists of a feed hopper, rotating plate, discharge outlet, control system, and pneumatic components, designed for easy assembly, cleaning, and maintenance in laboratory settings.

| Model | SP-250 | |

| Batch capacity | 50–500g/batch | |

| Spheronizing time | 0.5–3.0min/batch | |

| Rotation speed | 50–1400rpm | |

| Qualified rate | ≥90% | |

| Compressed air | Pressure | 0.4–0.6Pa |

| Consumption | 0.4–0.5m³/min | |

| Power supply | 3 phase,380V single phase,220V | |

| Motor power | 0.75kW | |

| Noise level | <60dB | |

| Overall dimensions (L×W×H) | 650×530×700mm | |

| Net weight | Approx. 30kg | |