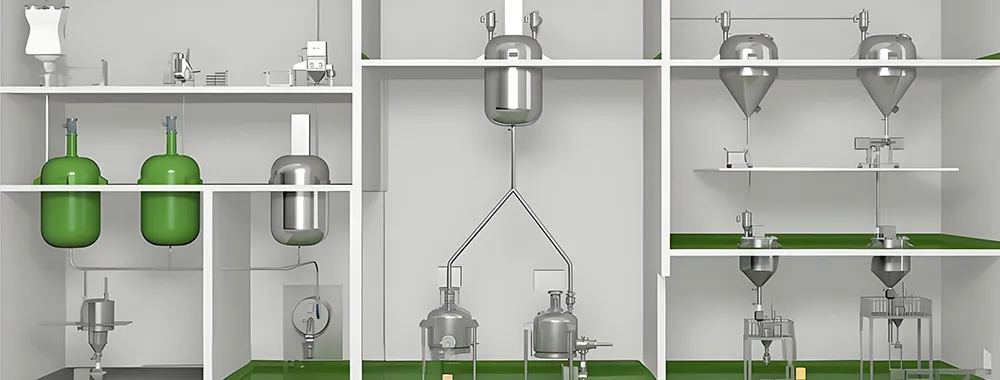

Integrated Powder Handling System (Mixing/Sifting/Filling)

Double cone mixer, rotary centrifugal sifter, vacuum conveying equipment and gravimetric filling machine

This integrated powder handling system is designed for automated, dust-free powder processing from mixing and sifting to conveying and packaging. The material is first homogenized in a double cone mixer, then transferred by Vacuum Conveyor 1 to Silo #1. It passes through a rotary centrifugal sifter to separate material according to specified particle sizes, with qualified powder collected in Silo #2. The screened powder is conveyed again via Vacuum Conveyor 2 to Silo #3, where it is precisely weighed and packaged using a gravimetric filling system.

- Double cone mixer

- Rotary centrifugal sifter

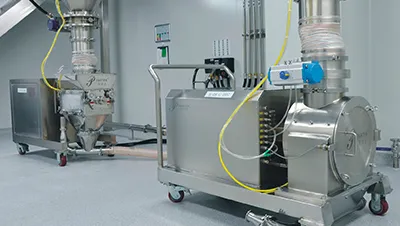

- Vacuum conveying equipment

- Rotary valve gravimetric filling machine

The entire powder handling process is fully enclosed and PLC-controlled, compliant with the latest GMP standards for dust-free and hygienic powder handling environments.

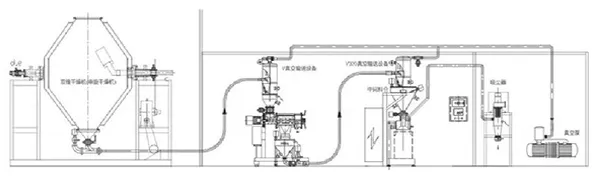

A combined double cone sifting and hammer mill system is available for fine powder processing. This configuration includes a rotary sifting silo integrated with a CFJ-15 hammer mill, enabling continuous, high-efficiency grinding after homogeneous mixing and direct transfer through a closed pipeline.

This integrated powder processing system is ideal for industries requiring precise powder quality control, contamination-free operation, and continuous production efficiency.