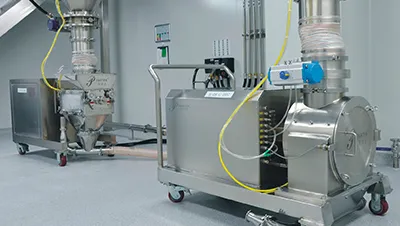

Horizontal Pelletizing Extruder

Radial screw extruder for producing cylindrical extrudates through perforated screens

In this horizontal extrusion system, the pre-mixed wet mass is driven by a screw feeder into the extrusion chamber, where it is compressed through a perforated screen to form dense, uniform cylindrical strands of varying lengths. The extruder is composed of a motor, gearbox, transmission assembly, feed hopper, screw feeder, extrusion chamber, perforated plate, screw cap, control system, and a rigid support frame.

Specifications

| Model | ||||

| Production capacity (based on Ø 0.8mm) | ≤6kg/h | ≤40kg/h | ≤80kg/h | ≤160kg/h |

| Min. feeding weight | 0.2kg | 0.5kg | 1.2kg | 2.0kg |

| Die aperture | 0.4–3.5mm | |||

| Rotation speed | 5–120rpm | |||

| Material return ratio | ≥99% | |||

| Power supply | 380V,50Hz | |||

| Motor power | 1.5kW | 3kW | 4kW | 7kW |

| Noise level | <45dB | <45dB | <45dB | <50dB |

| Overall dimensions (L×W×H) | 550×450×610mm | 700×360×470mm | 1125×650×1180mm | 1280×750×1250mm |

| Net weight | 90kg | 300kg | 660kg | 880kg |

Features

- Flexible product sizing

Equipped with multiple interchangeable perforated screens for producing cylindrical extrudates ranging from 0.5mm to 3.0mm in diameter. - Low-shear radial extrusion Compared with single-screw extruders, the radial screw design applies less shear force, minimizing friction and heat generation. This enhances plastic deformation while maintaining the stability of heat-sensitive materials during processing.

- Thermal adaptability The extruder can be equipped with a cooling or heating jacket to meet the specific requirements of different material types.