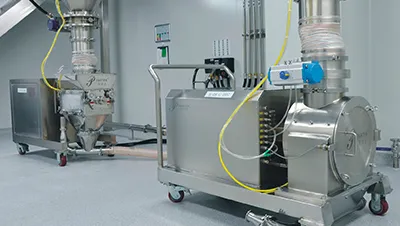

Vertical Pelletizing Extruder (Cooling Type)

Pharma extruder with an integrated cooling mechanism to handle heat-sensitive materials for pharmaceutical products and drugs

The cooling-type vertical pelletizing extruder is an advanced model developed based on the standard vertical design, enhanced with integrated cooling, anti-slipping, and precise temperature control functions. It is engineered for processing temperature-sensitive materials used in pharmaceutical production.

| Model | |||||||

| Min. feeding weight | 0.15kg | 0.3kg | 0.5kg | 0.5kg | 1kg | 2kg | 2kg |

| Production capacity (based on Ø 0.8mm) | ≤50 | ≤80kg/h | ≤120kg/h | ≤150kg/h | ≤260kg/h | ≤360kg/h | ≤500kg/h |

| Die aperture | Ø0.4–3.0mm | Ø0.5–3.0mm | Ø0.5–3.0mm | Ø0.5–3.0mm | Ø0.5–3.0mm | Ø0.6–3.0mm | Ø0.6–3.0mm |

| Power supply | 380V,50Hz | ||||||

| Rotation speed | 5–95rpm | ||||||

| Material return ratio | ≥99% | ||||||

| Noise level | <45dB | <45dB | <45dB | <60dB | <60dB | <60dB | <60dB |

| Overall dimensions (L×W×H) | 86×70×16 cm | 95×80×160cm | 135×100×162cm | 135×110×162cm | 150×110×165cm | 165×115×165cm | 165×120×165cm |

| Weight | 380kg | 600kg | 800kg | 1000kg | 1200kg | 1500kg | 1800kg |

- Efficient temperature control

The cooling system maintains the extrusion zone within a temperature rise of ≤5 °C (with chilled water) or ≤10 °C (with tap water), ensuring stable operation without heat buildup. - Stable material feeding

The extruder prevents material slippage during processing, maintaining uniform extrusion and consistent product quality. - Reliable sealing and easy maintenance

Equipped with a main inlet and outlet for cooling water, featuring quick-connect couplings for easy setup and disassembly without leakage. - Continuous production for heat-sensitive materials

Enables efficient continuous extrusion for temperature-sensitive compounds, improving productivity and expanding material compatibility. - Automated temperature monitoring

The system continuously measures and regulates the material temperature in real time, ensuring optimal process conditions.

Ideal for the production of heat-sensitive pharmaceutical pellets and sustained-release formulations such as ibuprofen extended-release micro-pellets, as well as other active pharmaceutical ingredients (APIs) requiring precise temperature control during extrusion.

This extruder is typically paired with a spheronizer to form a complete pelletizing system.