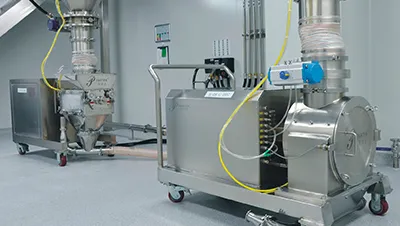

Integrated Extrusion-Spheronization System (Gravimetric Control Type)

Pelletizing system integrating extrusion and spheronization with precise gravimetric control of extrudate feed rate

The gravimetric extrusion-spheronization system combines a vertical rotary extruder and a centrifugal spheronizer with automated feed rate control for stable, continuous pellet production. The process begins with pre-mixed wet granules fed from the auxiliary hopper into the screw feeder. The material is evenly delivered into the vertical rotary extruder, where it is pressed and extruded through perforated screens to form short cylindrical extrudates. These extrudates fall by gravity into the intermediate timing hopper, which periodically releases batches into the spheronization chamber. Inside the centrifugal spheronizer, mechanical forces including centrifugal motion, shearing, and friction transform the cylinders into smooth, uniformly sized spheres, which are then discharged through the pneumatic outlet valve.

| Model | ||||||||

| Vertical pelletizing extruder | Hopper capacity | 6 L | 12 L | 16 L | 20 L | 22 L | 26 L | 30 L |

| Feeding motor power | 1.5kW | 2.2kW | 2.2kW | 2.2kW | 3.0kW | 3.0kW | 3.0kW | |

| Extrusion motor power | 2.2kW | 5.5kW | 5.5kW | 5.5kW | 7.5kW | 11.0kW | 11.0kW | |

| Extrusion speed | 5–95rpm | |||||||

| Die hole diameter | Ø0.4–3.0mm | Ø0.5–3.0mm | Ø0.5–3.0mm | Ø0.5–3.0mm | Ø0.5–3.0mm | Ø0.6–3.0mm | Ø0.5–3.0mm | |

| Extrusion capacity (based on Ø0.8mm) | ≤50kg/h | ≤80kg/h | ≤120kg/h | ≤150kg/h | ≤260kg/h | ≤360kg/h | ≤500kg/h | |

| Feeding hopper | Hopper capacity | 12L | 20L | 26L | 30L | 36L | 40L | 46L |

| Butterfly valve diameter | 200mm | 250mm | 300mm | 300mm | 350mm | 400mm | 400mm | |

| Centrifugal spheronization machine | Inner diameter | 400mm | 600mm | 750mm | 750mm | 750mm | 1000mm | 1000mm |

| Motor power | 1.5kW | 3.0kW | 3.0kW | 3.0kW | 3.0kW | 7.5kW | 11kW | |

| Disc rotation speed | 50-1050rpm (adjustable) | |||||||

| Blower power | 0.18kW | 0.37kW | 0.37kW | 1.5kW | 1.5kW | 2.2kW | 4kW | |

| Exhaust fan power | 0.18kW | 0.55kW | 0.55kW | 0.75kW | 0.75kW | 1.5kW | 2.2kW | |

| Spheronization time | 0.5-4.0min/batch | |||||||

| Spheronization capacity | ≤1.6kg/batch | ≤3.0kg/batch | ≤8.0kg/batch | ≤8.0kg/batch | ≤8.0kg/batch | ≤20.0kg/batch | ≤20.0kg/batch | |

| Material collection rate | 98% | |||||||

| Compressed air | Pressure | 0.4-0.6MPa | ||||||

| Consumption | 0.12-0.2m³/min | |||||||

| Overall dimensions (L×W×H) (for reference) | 1370×850×1600mm | 1840×900×2230mm | 1940×1200×2500mm | 940×1200×2500mm | 1940×1200×2500mm | 2300×1440×3000mm | 2300×1440×3000mm | |

| Total weight (for reference) | 580kg | 960 kg | 1400 kg | 1600 kg | 1800 kg | 2500 kg | 2800 kg | |

- Product yield exceeds 99%, with narrow particle size distribution and high qualification rate (>90%)

- Produces dense, smooth, and high sphericity pellets (density up to 0.8 g/cm³), ideal for coated or controlled-release formulations

- Low-noise operation (<70 dB), minimal operator intervention, and clean, dust-free production environment

Pharmaceutical pellets

Pharmaceutical pellets Sustained-release drug cores

Sustained-release drug cores