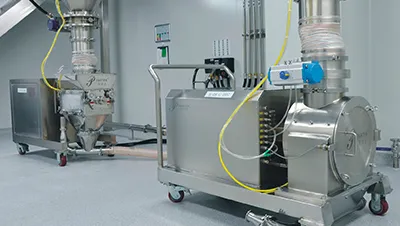

Production-Scale Spheronizer (Marumerizer)

Centrifugal spheronizer for converting cylindrical extruded granules into spheres of uniform size

The production-scale spheronizer transforms cylindrical extrudates into perfectly rounded pellets of uniform size through a high-speed centrifugal process. As the extruded material enters the chamber, the rotating disc with breaker teeth cuts it into uniform short cylinders. Under the combined forces of centrifugal motion, friction between the particles, wall, and disc, and airflow within the chamber, the granules undergo continuous three-dimensional rolling and tumbling. This uniform kneading motion shapes the particles into smooth, consistent spheres.

The spheronizeation equipment consists of a feed hopper, product chamber, rotating disc, discharge assembly, optional air exhaust and dehumidification cabinet, control system, and pneumatic system. Custom configurations are available to suit various research or process requirements.

| Model | |||||

| Batch capacity | ≤0.8kg/batch | ≤1.6kg/batch | ≤2.5kg/batch | ≤8.0kg/batch | ≤20.0kg/batch |

| Spheronizing time | 0.5–4.0min/batch | ||||

| Rotation speed | 50–1400rpm | 50–1400rpm | 50–1400rpm | 50–1300rpm | 50–600rpm |

| Qualified rate | >90% | ||||

| Compressed air pressure | 0.4–0.6MPa | ||||

| 0.1–0.5m³/min | |||||

| Power supply | 380V,50Hz | ||||

| Motor power | 1.5dB | 2.2dB | 4dB | 7.5dB | 11dB |

| Noise level | 700×450×1000mm | 800×500×1100mm | 1380×750×1300mm | 1500×900×1300mm | 1800×1200×1400mm |

| Overall dimensions (L×W×H) | 100kg | 200kg | 360kg | 600kg | 1000kg |

Pharmaceutical micro-pellets

Pharmaceutical micro-pellets Sustained-release drug carrier spheres

Sustained-release drug carrier spheres

This spheronizer can be integrated with Partek’s extruders to form a complete pelletizing system.