Is the equipment suitable for powders or granules used in pharmaceutical, food, or chemical production?

Can the equipment handle high-temperature, viscous, flammable, explosive, or corrosive materials?

Does the equipment comply with GMP requirements?

Can the production line be customized to match specific output targets and plant layout constraints?

Can electrical specifications and control systems match local standards in different countries?

What is the typical delivery time?

Are commissioning and training services available?

Is product testing available before purchase?

Can full process lines be designed, not just single machines?

How is the equipment packaged and transported?

What after-sales support is provided?

What is included in a quotation, and are there hidden costs?

Can certification documents such as ISO and CE be provided?

Can documentation be supplied in different languages?

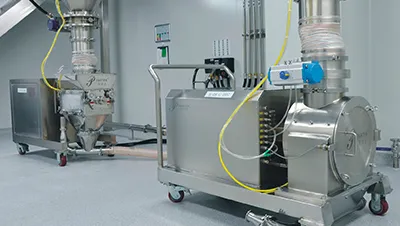

Can the containment discharging isolator help control dust and improve air quality in the workshop?

Can the equipment be integrated with existing production lines?

How does the glovebox ensure safety when handling highly toxic pesticide powders?

The containment discharging system achieves complete operator–material isolation through a triple protection design:

- Glovebox containment chamber allows material handling without direct contact.

- Negative pressure dust extraction captures 100% of airborne dust during charging.

- SS316L stainless steel construction resists pesticide corrosion and extends service life by up to three times.

How is oxidation and explosion risk controlled when processing lithium battery materials?

A dual protection approach combining explosion-proof and inerting systems is applied:

- Explosion-proof design includes ATEX-certified motor and system-wide grounding.

- Oxygen monitoring continuously measures oxygen concentration and automatically initiates nitrogen purging when exceeding 5% LEL.

- Anti-oxidation system nitrogen protection interface maintains oxygen concentration below 1%.

- Closed transfer to reactor prevents air exposure during powder conveying.

What are the main advantages of the BVP continuous vacuum feeder?

What are the differences between the CVF continuous vacuum feeder and a traditional intermittent vacuum feeder?

Can the CVF continuous vacuum feeding system be customized and integrated with other equipment, such as mixers or batching systems?

Can the mobile vacuum feeder automatically adjust to different feeding heights? What is the lifting range?

What types of materials are suitable for the hammer mill?

How does the CFJ hammer mill differ from standard hammer mills?

Is the hammer mill easy to clean and compliant with GMP regulations?

Does the milling process generate heat or dust, and is it suitable for heat-sensitive materials?

What types of materials is this mill suitable for?

What is the typical production capacity? Can it support continuous operation?

Which model is recommended for wet material milling requiring uniform particle size distribution?

What are the advantages of this mill compared with traditional hammer or high-speed mills?

Can the particle size be adjusted? Is it easy to change components?

How does the filling system ensure a high level of cleanliness? Can it meet GMP cleanroom requirements?

How does the dust-free filling system prevent clogging when handling viscous or poorly flowing materials?

Can the gravimetric filling system be connected to an existing production line for full automation?

The design of dust-free gravimetric filling machine supports seamless process integration with an existing production line.

- Upstream connection: compatible with vibrating feeding stations, pulverizers, and fluid bed dryers to enable a fully automated “unpacking → grinding → drying → packaging” workflow

- Smart control: centralized PLC system with touchscreen interface for parameter settings, fault diagnostics, and production data recording

- Case example: in an inulin production line, integration of wet granulation, extrusion, drying, and dust-free packaging increased overall production efficiency by 40%

Which industries is the FIBC filling machine suitable for?

What level of weighing accuracy can be achieved?

How fast is the filling process?

Can the FIBC filling machine be connected to other production line equipment?

How does the weighing and dispensing system ensure uninterrupted production?

It employs a dual-buffer design to maintain continuous operation:

- Inlet buffer chamber allows preloading of 8–12 bottles, functioning like an “ammunition depot” for constant supply.

- Empty bottle storage chamber acts as a “reserve unit,” storing up to 20% backup containers for seamless bottle replacement without process interruption.

How is contamination prevented when handling fine or dusty nanomaterials?

The containment isolator system incorporates a three-level dust control strategy:

- Vertical auger filling ensures smooth downward discharge, minimizing dust dispersion.

- Inflatable sealing gate limits powder escape to less than 0.01% during operation.

- Gas circulation system performs up to 15 air exchanges per hour within the chamber, maintaining a clean and stable environment.

What is the production capacity of the laboratory model? Can it scale up to pilot production?

Can the extrudate size and shape be customized?

What is the difference between the control system configurations, and how should I choose?

What industries and materials are suitable for the LXJ vertical rotary extruder?

This extrusion equipment is designed for pharmaceutical, chemical, and food applications. It processes blended mixtures of powders, excipients, and wet binders into soft, moldable materials. Typical examples include:

- Pharmaceuticals: soft material mixtures, pellet precursors

- Chemicals: catalyst carriers, granular additives

- Food: nutrient enhancers, flavoring bases

Its extrusion system is particularly suitable for continuous production of cylindrical extrudates with high uniformity.

Does the palletizing extruder meet GMP and CIP requirements for pharmaceutical use?

The vertical palletizing extrusion equipment fully complies with GMP and CIP standards:

- Design: modular structure with easy disassembly and polished internal surfaces free of dead corners

- Material: all contact parts made of 316L stainless steel

- Validation: DQ/IQ/OQ documentation templates provided for qualification and verification.

What are the key upgrades of the cooling type vertical palletizing extruder compared with a standard extruder?

Three major technical advancements distinguish the cooling type extruder:

- Precise temperature control: The extrusion zone maintains a temperature rise of ≤5 °C (with chilled water) or ≤10 °C (with tap water), effectively preventing degradation of heat-sensitive materials.

- Anti-slipping design: The extrusion chamber features a special surface treatment and an adaptive pressure control system, eliminating slippage and material blockage during operation.

- Intelligent monitoring: Real-time temperature monitoring and automatic adjustment of extrusion parameters ensure consistent processing and stable product quality.

Does this extruding equipment meet pharmaceutical industry compliance requirements?

It is fully compliant with pharmaceutical manufacturing standards:

- Material: All contact parts are made of 316L stainless steel in accordance with FDA requirements.

- Cleaning: Supports CIP/SIP cleaning with dead-space residue less than 0.01%.

- Documentation: Includes complete IQ/OQ/PQ validation documentation and SAT protocol covering the temperature control module.