Rotary Centrifugal Sifter (Twin Shaft)

Dual-drive centrifugal screener machine for high-capacity scalping and sifting of bulk solid materials

The twin-shaft rotary centrifugal sifter features a dual-motor system, independently controlling the feed screw and sifting chamber. Material is conveyed by the screw into the rotating chamber, where high-speed blades perform efficient sieving and filtration. Oversized particles are automatically discharged through the coarse outlet for further processing. Independent control of feed rate and sifting speed allows precise operation and significantly improves screening efficiency.

| Item | Product contact parts | Non-contact parts |

| Material | AISI-316L stainless steel | AISI-304 stainless steel |

| Surface finish | Ra≤0.8μm,polished finish | Ra≤1.4μm,ground finish |

| Welding | Ground and polished | Pickled and ground |

| Processing capacity | 1000kg/h | |

| Rotation speed | 1500rpm | |

| Power | 3.0kW | |

| Net weight | 340kg | |

- Fully enclosed design to prevent contamination and ensure a clean working environment

- Minimal clearance between blades and screen to avoid metal-to-metal contact

- Easy and quick disassembly for maintenance and cleaning

- Gas-sealed bearings ensure reliable and hygienic operation

- Variable speed adjustment with digital speed display available

- Integrated and compact structure for user-friendly operation and optimal sieving performance

Pigments

Pigments Food additives

Food additives Active pharmaceutical ingredients (APIs)

Active pharmaceutical ingredients (APIs)

Depending on material properties and target particle size, different screen sizes can be customized. For heat-sensitive materials, an optional cooling system can be equipped to maintain product stability and prevent thermal degradation.

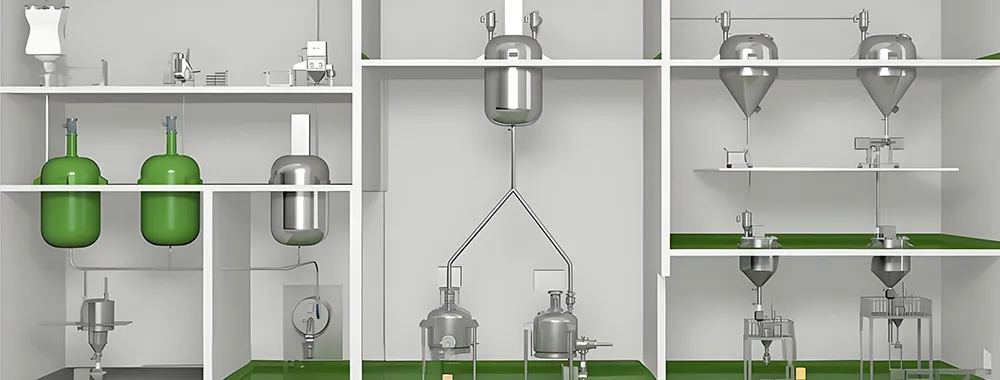

This twin-shaft rotary centrifugal sifter can be integrated with our vacuum feeder and hammer mill to form a complete processing line, tailored to meet various customer requirements.