Gravimetric Filling Machine (with Vertical Auger Filler)

Servo-driven powder packaging machine for filling free-flowing powders and granules into 5kg to 60kg bags

Ideal for filling free-flowing powders and granules into 5kg to 60kg bags, this filling machine with vertical auger filler uses a precision servo drive motor to drive the screw shaft, providing faster response, smoother acceleration and deceleration, and higher motion accuracy compared to conventional auger fillers. The result is improved filling precision and faster packaging performance. The system consists of the main filling valve, servo-driven auger filling unit, pipeline metal detector, pneumatic bag clamping device, weighing module and control system, and an integrated dust collection system. Mounted on a compact frame with mobile casters, it features a modular design for convenient cleaning and maintenance.

For easy dry and wet cleaning between production batches, the screw housing adopts a quick-release clamping design, while the feeding section is mounted on a linear slide rail for effortless removal and cleaning. The metal detector is also installed on a sliding track for quick disassembly and maintenance. To accommodate different bag sizes and heights, the filling head features an adjustable height design, ranging from 400mm to 600mm above the roller platform. The gravimetric filling machine supports laminar flow installation, offering a compact footprint ideal for cleanroom environments.

| Packaging range | 5–60kg |

| Packaging accuracy | ±20g |

| Packaging capacity | 2000kg/h (accuracy: ±50g) |

| ≤1000kg/h (accuracy: ±20g) | |

| 500kg/h (accuracy: ±10g) | |

| Bag clamping method | Pneumatic clamping |

| Feeding method | Vacuum feeding |

- High-precision weighing

Servo motor controls auger rotation, achieving accuracy up to ±20 g, with maximum precision of ±10 g - Explosion-proof certification

Complies with ATEX standards, suitable for environments with flammable or explosive powders/gases such as in chemical or pharmaceutical production - Flexible production capacity

Filling capacity ranges from 500–2000kg/h, adaptable for both small batch and continuous production - Cleanroom compatibility

Supports laminar flow installation with a compact footprint suitable for cleanroom environments - Wide material adaptability

Handles 5–60kg bags, compatible with both powder and granular materials - Dust-free sealed operation

Integrated WIP/CIP cleaning system (optional) eliminates cross-contamination and ensures hygienic operation

Free-flowing pharmaceutical powders and granules, such as amoxicillin API powder

Free-flowing pharmaceutical powders and granules, such as amoxicillin API powder Free-flowing natural extracts, such as inulin

Free-flowing natural extracts, such as inulin Starches with good flowability, such as corn starch

Starches with good flowability, such as corn starch

Bag Handling System

| Options | Function Description |

| Inner bag opening support / roll-type sealing device | Automated bag opening and sealing to reduce manual intervention |

| Inner bag support device (automatic connection) | Accurately positions the bag mouth to prevent filling deviation |

| Pre-filling gas injection system | Injects inert gas (e.g.,N₂) into the bag to prevent material oxidation |

| Pre-sealing air extraction system | Removes air inside the bag through vacuum extraction to extend shelf life |

Safety and Cleaning

| Options | Function Description |

| WIP/CIP cleaning system | In-place washing and sterilization in compliance with FDA 21 CFR Part 11 requirements |

| N₂ protection system | Provides full inert gas coverage to protect sensitive materials |

Bag Compatibility

| 5 Parameters | Customization Range |

| Bag capacity | 5–60kg (expandable) |

| Inner bag diameter | Ø300–800mm |

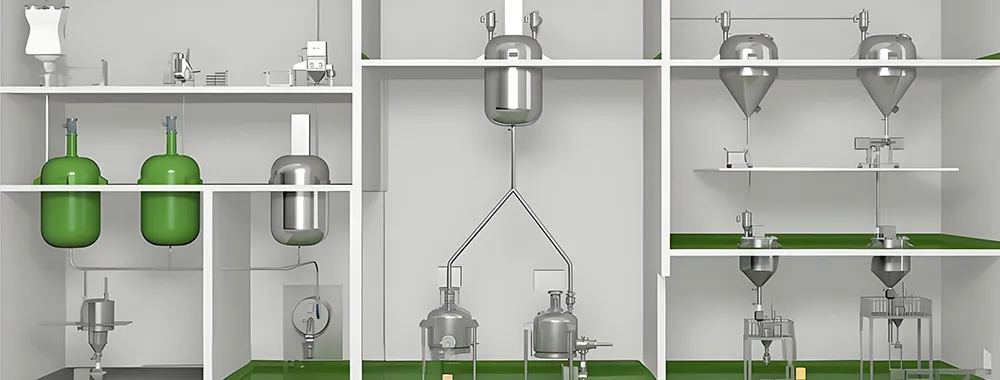

This gravimetric filling machine can be integrated with our vacuum conveyor, mixer, and mill to form a complete production line, meeting various customer process requirements.