Gravimetric Filling Machine (with Horizontal Auger Filler)

Servo-driven powder packaging machine for filling free-flowing powders and granules into 5kg to 50kg bags

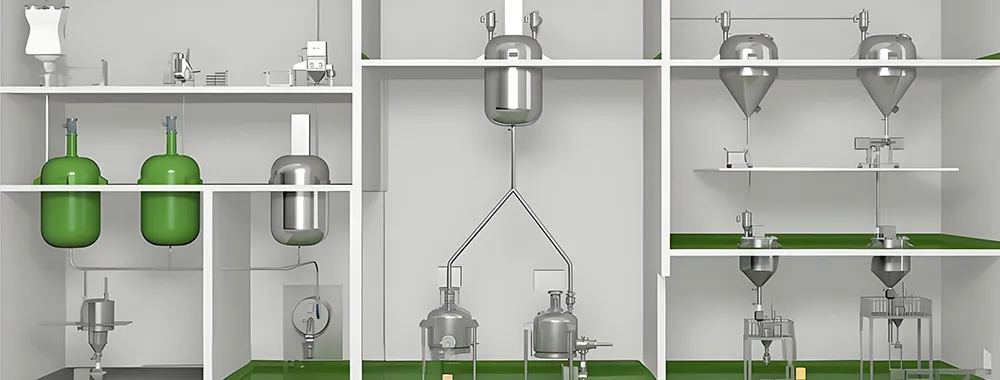

The servo-driven auger filling system controls the auger shaft through a servo motor. Compared with traditional auger fillers, the servo-driven design offers faster start/stop response and higher motion precision, ensuring faster packaging speeds and consistent accuracy. The powder packaging machine consists of a main filling valve, servo auger feeding unit, in-line metal detector, pneumatic bag clamping device, weighing module, weighing control system, and dust collection unit all integrated into a compact structure mounted on a mobile frame for easy relocation.

For simplified dry and wet cleaning during batch changeovers, the auger housing adopts a quick-release clamp design, while the feeding section uses a linear rail for easy removal and cleaning of the auger. The metal detector is also mounted on a sliding rail for convenient disassembly and maintenance. To accommodate bags of different heights, the filling head is designed with adjustable height positioning, compatible with conveyor table heights between 400mm and 600mm. The horizontally extended layout makes it ideal for facilities with limited ceiling height.

| Packaging range | 5kg–50kg |

| Packaging accuracy | ±20g |

| Packaging capacity | 2000kg/h (accuracy:±50g) |

| ≤1000kg/h (accuracy:±20g) | |

| 500kg/h (accuracy:±10g) | |

| Bag clamping method | Pneumatic bag clamping |

| Feeding method | Vacuum feeding |

- High-precision measurement

Servo motor controls auger speed, achieving an accuracy of ±20 g and up to ±10 g at maximum precision - Explosion-proof certification

Complies with ATEX standards, suitable for combustible or explosive powder/gas environments such as chemical and pharmaceutical industries - Flexible capacity range

Filling capacity from 500–2000kg/h, adaptable for both small-batch customized and continuous production Cleanroom compatibility Supports installation inside laminar flow rooms with a compact footprint - Wide material adaptability

Handles 5–60kg bags, compatible with both powders and granules - Dust-free and enclosed operation

Integrated WIP/CIP cleaning system (optional) for efficient cleaning and prevention of cross-contamination

Viscous materials such as BASF titanium dioxide

Viscous materials such as BASF titanium dioxide Bridge-forming materials such as protein powder

Bridge-forming materials such as protein powder

Bag Handling System

| Options | Function Description |

| Inner bag opening support / roll-type sealing device | Automated bag opening and sealing to reduce manual intervention. |

| Inner bag support device (automatic connector) | Precisely secures the bag mouth to prevent misalignment during filling. |

| Gas injection device before filling | Injects inert gas (e.g.,N₂) into the bag to prevent material oxidation. |

| Air evacuation device before sealing | Vacuum removes air from the bag before sealing,extending product shelf life. |

Safety and Cleaning

| Options | Function Description |

| WIP/CIP cleaning system | In-place cleaning and sterilization compliant with FDA 21 CFR Part 11 standards. |

| N₂ protection system | Provides full inert gas coverage to protect sensitive materials. |

Bag Compatibility

| Parameters | Customization Range |

| Bag capacity | 5– 60kg (expandable range) |

| Inner bag diameter | Ø300–800mm |