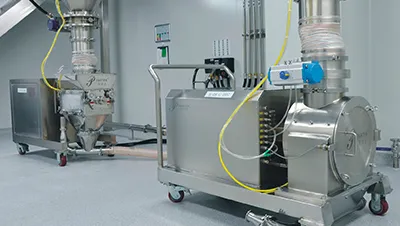

Integrated Extrusion-Spheronization System

Pelletizing system combining extruder and spheronizer for producing consistently sized spherical pellets

The integrated extrusion–spheronization system combines extrusion and rounding functions within a single, continuous process. Moist granulated material produced by a mixer is fed into the auxiliary hopper at the top of the unit. The screw feeder delivers the material evenly to the vertical extruder, where it is pressed and shaped through a perforated screen into short cylindrical extrudates. These extrudates then fall by gravity into a timed valve chamber, which intermittently transfers batches into the centrifugal spheronizing chamber. Inside, the rotating plate and frictional forces between particles, chamber wall, and airflow ensure consistent rounding, producing smooth, dense, and uniform pellets that are discharged through a pneumatic gate.

| Model | ||||||||||

| Vertical Rotary | Hopper capacity | 6L | 12L | 16L | 20L | 22L | 26L | 30L | ||

| Feeding motor power | 1.5kW | 2.2kW | 2.2kW | 2.2kW | 3.0kW | 3.0kW | 3.0kW | |||

| Extrusion motor power | 2.2kW | 5.5kW | 5.5kW | 5.5kW | 7.5kW | 11.0kW | 11.0kW | |||

| Extrusion speed | 5–95rpm | |||||||||

| Die hole diameter | Ø0.4–3.0mm | Ø0.5–3.0mm | Ø0.5–3.0mm | Ø0.5–3.0mm | Ø0.5–3.0mm | Ø0.6–3.0mm | Ø0.5–3.0mm | |||

| Extrusion capacity (based on Ø0.8mm diameter) | ≤50kg/h | ≤80kg/h | ≤120kg/h | ≤150kg/h | ≤260kg/h | ≤360kg/h | ≤500kg/h | |||

| Feeding hopper | Hopper capacity | 12L | 20L | 26L | 30L | 36L | 40L | 46L | ||

| Rotary valve diameter | 200mm | 250mm | 300mm | 300mm | 350mm | 400mm | 400mm | |||

| Centrifugal spheronization machine | Inner diameter | 400mm | 600mm | 750mm | 750mm | 750mm | 1000mm | 1000mm | ||

| Motor power | 1.5kW | 3.0kW | 3.0kW | 3.0kW | 3.0kW | 7.5kW | 11kW | |||

| Disc rotation speed | 50-1050r/min (adjustable) | |||||||||

| Blower power | 0.18kW | 0.37kW | 0.37kW | 1.5kW | 1.5kW | 2.2kW | 4kW | |||

| Exhaust fan power | 0.18kW | 0.55kW | 0.55kW | 0.75kW | 0.75kW | 1.5kW | 2.2kW | |||

| Spheronization time | 0.5-4.0min/batch | |||||||||

| Spheronization capacity | ≤1.6kg/batch | ≤3.0kg/batch | ≤8.0kg/batch | ≤8.0kg/batch | ≤8.0kg/batch | ≤20.0kg/batch | ≤20.0kg/batch | |||

| Material collection rate | 98% | |||||||||

| Compressed air | Pressure | 0.4-0.6MPa | ||||||||

| Consumption | 0.12-0.2m³/min | |||||||||

| Overall dimensions (L×W×H) (for reference) | 1370×850×1600mm | 1840×900×2230mm | 1940×1200×2500mm | 940×1200×2501mm | 1940×1200×2500mm | 2300×1440×3000mm | 2300×1440×3000mm | |||

| Total weight (for reference) | 580kg | 960kg | 1400kg | 1600kg | 1800kg | 2500kg | 2800kg | |||

- Streamlined design integrates extrusion and spheronization, reducing manual handling and floor space while maintaining quiet operation (<70 dB)

- High production efficiency with yields above 99% and a narrow particle size distribution; over 90% of pellets meet target size specifications

- Excellent pellet quality: uniform sphericity, low friability, and high density (>0.8 g/cm³), ideal for producing evenly coated controlled-release pellets

Pharmaceutical pellets

Pharmaceutical pellets Sustained-release drug carrier spheres

Sustained-release drug carrier spheres

It can be further integrated with the IBC mobile intermediate bulk container (IBC) system for efficient, continuous material transfer and handling.