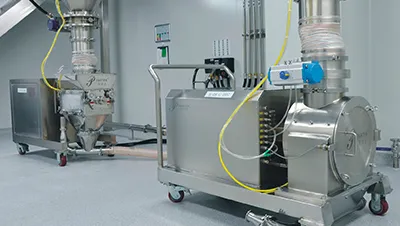

Vertical Pelletizing Extruder (Production-Scale)

Basket extruder for large-volume pellet manufacturing

The production-scale vertical pelletizing extruder is designed for large-volume manufacturing of uniform cylindrical pellets. It processes blended mixtures of powders, excipients, and wet binders into dense, consistent extrudates through a rotary extrusion mechanism. The material is evenly fed into the extrusion chamber by a rotating shaft feeder and compressed through the die plate to achieve smooth and continuous extrusion.

| Model | ||||||

| Min. feeding weight | 0.3kg | 0.5kg | 0.5kg | 1kg | 2kg | 2kg |

| Production capacity (based on Ø0.8mm) | ≤80kg/h | ≤120kg/h | ≤150kg/h | ≤260kg/h | ≤360kg/h | ≤500kg/h |

| Die aperture | Ø0.5–3.0mm | Ø0.5–3.0mm | Ø0.5–3.0mm | Ø0.5–3.0mm | Ø0.6–3.0mm | Ø0.6–3.0mm |

| Power supply | 380V,50Hz | |||||

| Rotation speed | 5–95rpm | |||||

| Material return ratio | ≥99% | |||||

| Noise level | <45dB | <45dB | <60dB | <60dB | <60dB | <60dB |

| Overall dimensions (L×W×H) | 950×800×1600mm | 1350×1000×1620mm | 1350×1100×1620mm | 1500×1100×1650mm | 1650×1150×1650mm | 1650×1200×1650mm |

| Weight | 600kg | 800kg | 1000kg | 1200kg | 1500kg | 1800kg |

- Continuous and efficient operation

Supports uninterrupted feeding, extrusion, and shaping within an integrated process, ensuring high throughput and stable production. - Uniform extrusion with high yield

Maintains consistent pressure distribution for even density across extrudates, achieving a finished product rate of ≥99% and minimizing waste. - Low-temperature, friction-free extrusion

Employs a rotary extrusion mechanism that prevents heat generation during processing, ideal for heat-sensitive materials such as pharmaceuticals or biological formulations. Compared with twin-screw extruders, it requires no external cooling, reduces energy use, and eliminates die plate cracking risks, simplifying maintenance and operation. - Safe and stable performance

Equipped with overload protection and low-noise operation (<45 dB), ensuring operational safety and a comfortable working environment. - Flexible die configuration

Offers multiple die plate sizes (Ø0.4mm-3.0mm), capable of producing uniform cylindrical extrudates from 0.5mm to 3.0mm, meeting diverse production-scale requirements.

Extrusion performance of soft materials blended from herbal extract powder and excipients such as microcrystalline cellulose and lactose

This extruder is typically paired with a spheronizer to form a complete pelletizing system.