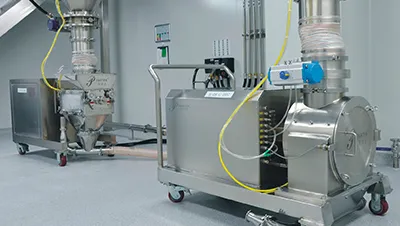

Continuous Vacuum Feeder, CVF Series

Enclosed vacuum conveyor for continuous transferring of powders and granules to downstream powder processing equipment

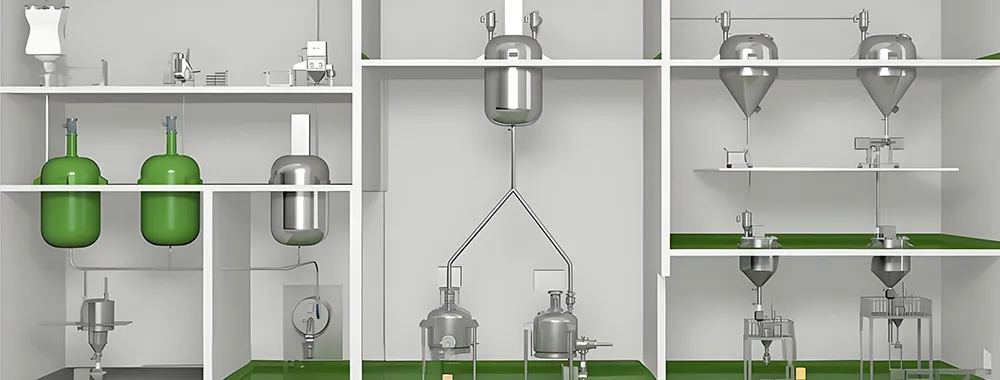

The CVF continuous vacuum feeding system consists of a vacuum valve chamber, isolation chamber, filter unit, reverse air cleaning system, feeding mechanism, and rotary airlock valve. It enables both continuous material feeding and continuous discharge, significantly enhancing conveying efficiency. The conveying system cam be integrated with other powder processing equipment such as milling, mixing, or screening machines to form a complete continuous conveying line that replaces positive pressure conveying and eliminates dust leakage or explosion risks.

| Model | ||||

| Vacuum generator model | VTML100 | VTML200 | VTML400 | VTML800 |

| Compressed air pressure | 0.5–0.8MPa | 0.5–0.8MPa | 0.5–0.8MPa | 0.5–0.8MPa |

| Working pressure | 0.5–0.8MPa | 0.5–0.8MPa | 0.5–0.8MPa | 0.5–0.8MPa |

| Air consumption | 0.4m³/min | 0.8m³/min | 1.8m³/min | 3.6m³/min |

| Conveying capacity | 0.2–0.6T/h | 0.6–1.8T/h | 1.8–3.0T/h | 3.0–6.0T/h |

| Filter type | Ti07 imported filter,PTFE filter,PE-HD filter,sintered titanium filter | Ti07 imported filter,PTFE filter,PE-HD filter,sintered titanium filter | PE-HD filter,sintered titanium filter | PE-HD filter,sintered titanium filter |

| Filter area | 0.3m² | 0.3m² | 0.9m² | 1.8m² |

| Suction inlet diameter | DN25 | DN50 | DN75–50 | DN100–75 or DN100 |

| Discharge outlet diameter | 150mm | 150mm | 200mm | 200mm |

| Effective hopper volume | 5L | 12L | 22L | 50L |

- Enables fully continuous material feeding and discharging

- Efficient use of electric vacuum source with no resource waste

- Supports conveying heights up to 30 m and distances up to 100 m, with capacities up to 8–10T/h

- Provides dust-free operation, minimizing environmental contamination and reducing the risk of powder explosions

Active pharmaceutical ingredients (APIs)

Active pharmaceutical ingredients (APIs) Monosodium glutamate (MSG)

Monosodium glutamate (MSG) Pigments

Pigments

The CVF continuous vacuum feeder can be integrated with small bag dumping stations, hammer mills, horizontal centrifugal sifters, and weighing and packaging systems to form a complete powder conveying line that meets diverse customer requirements.

To meet diverse process requirements, the system can be tailored in the following aspects:

- Structural dimensions

Customizable pipe diameter, hopper capacity, conveying height and distance, and interface configuration. - Exterior and material options

Material selection, polishing precision, surface finish, and dustproof or explosion-proof structure. - Functional modules

Control mode, filtration system, feeding and discharging methods, and additional functions such as CIP cleaning and alarm systems.